our latest projects & videos

examples of our International Tiltex installations

“The channel is looking great, Tiltex product has held really well through this recent rain event”

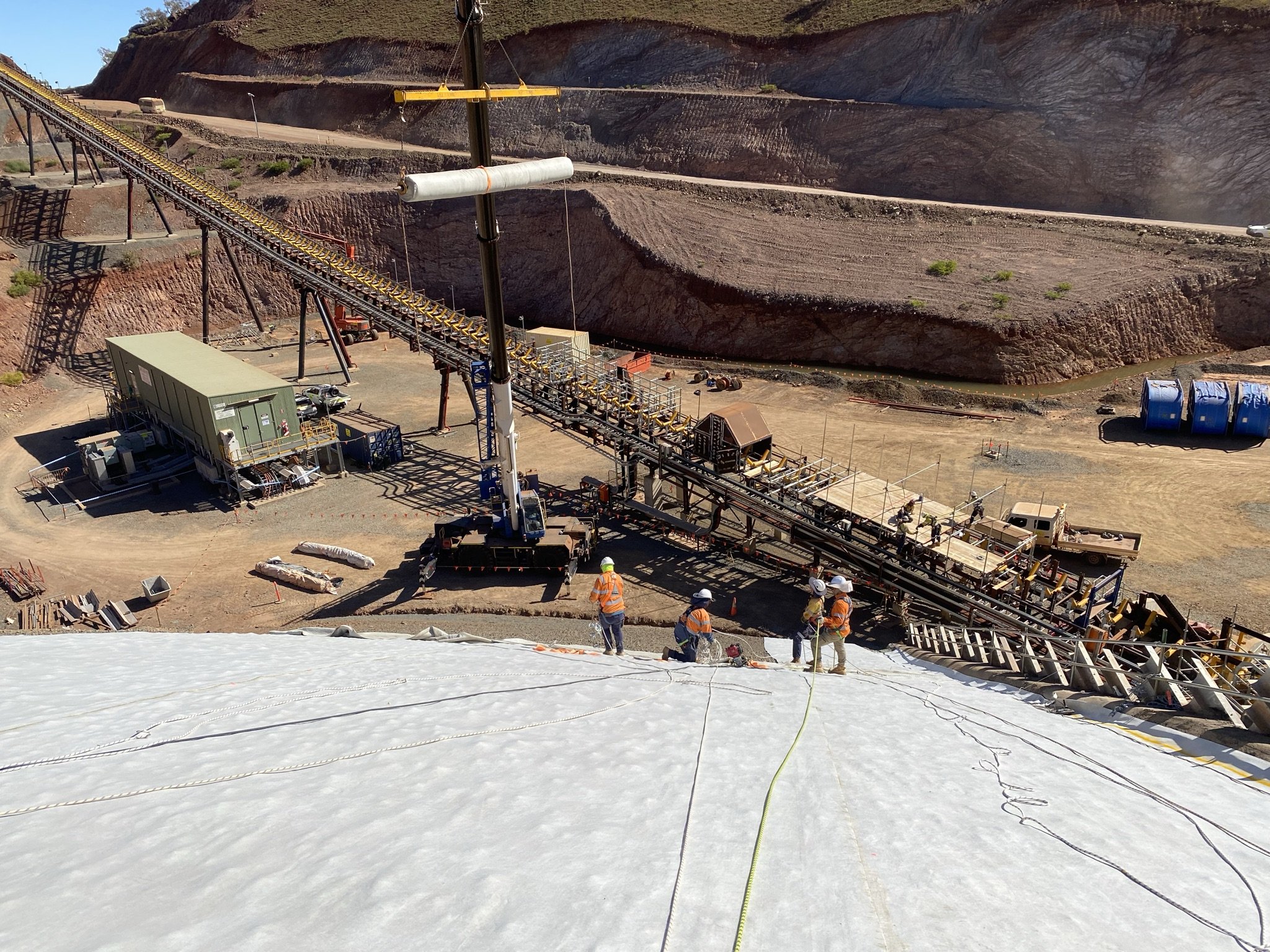

Water Infiltration Barrier & Erosion Control Protection to a Reinforced Earth Wall

Our Tiltex installation team have just completed a major water infiltration barrier & erosion control to the ROM Wall Crusher A project at Ironbridge Mine, Pilbara WA. Our team installed Tiltex 12B Anti Cracking 11,000psi Compressive Strength GCCM over 164 ft long steep batters at 1V:1.6H, secured with our soil anchor grid system designed to endure 164ft/sec winds.

Tiltex 12B GCCM was specified for covering slopes above the ROM Wall and its primary design is to inhibit water infiltration behind the metal facing wall panels and provide ground surface erosion protection of batter slopes. The project involved deploying the Tiltex 12B’s 16ft 4”wide x 65 ft long rolls longitudinally down the steep batters and seaming with our unique Tiltex B STAB 40 seaming system. Installing a soil anchor grid system at 6ft 6” grid pattern and perimeter soil anchors at 1 ft 7” spacing.

Hydrating Tiltex 12B GCCM on steep slopes is achievable with our exclusive Saturation Hydrator apparatus to provide an even distribution of water through Tiltex 12B’s matrix structure to ensure no unset cement and to initiate curing to 11,000psi Compressive Strength and 2235psi* Flexural Strength properties. *7 days

Phillips 66 remediation

PASSADENA USA

Tiltex b anti cracking gccm replaced rip rap & shotcrete

Tiltex 12B was recently specified for remediation of fuel bunds for Phillips 66 refinery in Pasadena USA to replace aged and cracked bituminous and shotcrete seal.

Installation was quick, ahead of schedule, with high end results improving the durability and safety around the fuel bunds.

aecom capping PROJECT

tiltex was chosen over rip rap & shotcrete

Aecom required a safe, cost effective and fast installation solution for their capping of asbestos and chemical protection to provide safety to their workers.

Tiltex B Anti Cracking GCCM was specified over previously used shotcrete and rip rap due to its smooth, protective surface, environmental considerations and guarantee of impermeability.

flood diversion channel

tiltex B ANTI CRACKING GCCM replaced 100mm concrete

Our client required a better solution for temporary and permanent erosion control of a main drainage channel during severe rain events over a large catchment area for a logistics infrastructure development project.

Tiltex B Anti Cracking GCCM replaced 100mm/3.9” concrete and was deployed longitudinally & equilaterally across the drainage channel where the channel curves.

Tiltex B Anti Cracking GCCM was 10 x faster to install than the previous used conventional FRP Concrete and the project was completed ahead of schedule.

The project was tested a month after installation with the highest rainfall in 38 years. The product performed perfectly.

State Rail Project

tiltex B anti-cracking gccm replaced 3.9”/100mm concrete

TILTEX B ANTI CRACKING NOW SPECIFIED FOR government RAILWAY UPGRADE PROJECTS

Tiltex B Anti Cracking GCCM is specified on a number of railway projects, working with major organisations such as John Holland and Laing O’Rourke.

Tiltex B was specified due to its exclusive anti-cracking enhancement properties, ease of installation, sustainable material benefits and cost savings over traditional 100mm/3.9” concrete which had previously been used.

As rail erosion control maintenance needs to be done as quickly as possible to maintain rail service, Tiltex B Anti Cracking GCCM was chosen as it’s ease of installation means railway maintenance can occur quickly with minimal disruption to railway services.

100m2/1076ft2 of Tiltex 12B can be installed every 20 minutes, making it a much faster installation than using shotcrete & concrete. It is also a more cost effective alternative than traditional erosion control methods.

Tiltex has a 50 year design life and a 30 year warranty* making it a long term erosion control and drainage solution.

HAWAII pilot project for highway drain application to re-open road

In Hawaii, a pilot project was completed using Tiltex B for a highway roadside drainage system that was previously washed away due to a major landslide. Due to it’s ease of application to existing road infrastructure and hot asphaltic road surfacing to Tiltex B, fast application time and 11,000psi compressive strength, Tiltex B Anti Cracking GCCM was found to be the most cost effective and quality choice to deliver a fast, strong drain application next to a major State Highway so that this road could open sooner than was planned.

Tiltex B installation had minimal traffic disruption with less equipment requirement at the roadside than with traditional concrete drain lining methods, which can add complexity and risk of safety and visibility hazards for vehicles and construction workers. It took approximalty 3 days to lay, secure and harden approximately 400ft of drainway so that they were able to apply the asphalt for re-opening of the road.

Waste Water Treatment Plant

tiltex was chosen over just HDPE liner to protect a community asset

Tiltex was specified to line 30,948m2/333121ft2 HDPE lined waste water effluent ponds to protect the liner from nature’s elements, prolong the liner’s operational life and to protect a vital community asset from damage which would have major issues for the community if the effluent ponds were damaged. .

Tiltex protects the HDPE liner against damage from UV degradation, wind up lift, temperature changes, animals, livestock and minimizes vandalism & fire damage.

See below for our video highlighting to vastness of the project and how well Tiltex protected this area.

mining spillway application

tiltex b anti cracking gccm chosen over rock pitching

Tiltex was chosen as a cost effective erosion control material over rock pitching at an Australia mine site.

Tiltex B was a much safer surface than previous rock pitching used with the benefit of strength from the 80MPa/11,000psi+ Compressive Strength properties and faster more cots effective installation times.

Due to Covid-19, our Tiltex engineers & installation team instructed our customer to install Tiltex B via specialised training and then on site video for direct installation guidance.

The installation ran went smoothly, the project was completed ahead of schedule easily with great results, whilst maintaining safety practices.

“The use of Tiltex product resulted in direct, measurable safety & risk management benefits for the project by introducing a new, cutting edge product to eliminate what was previously high risk, high labour intensive work on a 1:4 batter. Additional benefits from a time & cost perspective were also achieved.” Project Delivery Lead .

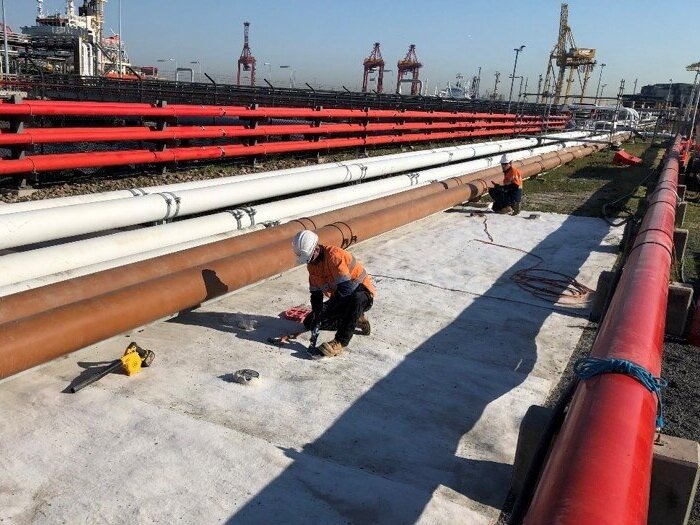

Capping Fuel Terminal Project

tiltex b anti cracking gccm was chosen over rip rap or shotcrete

Tiltex 12B was approved by the terminal operator, port authority and Environmental Protection Authority for capping ground under pipe service lines for fuel spillage control, reduced ground contamination and downtime for weed control.

Tiltex B Anti Cracking GCCM provided a smooth, safe and protected surface with PFAS & Asbestos contaminated soils being capped.

Tiltex can be used as a temporary or long term capping solution.

Estuary protection Project

tiltex b anti cracking gccm was chosen over quarry rock

This river estuary in Adelaide is inhabited by Australia’s largest salt water crocodile population. Our client used to track load 38 tonnes of quarry rock, 90 minutes away from site, to cover 17.2m2/185ft2 of river bank. It would take 3 truck loads a day to cover 51m2/548ft2 after unloading and placing the rock. One truck load of Tiltex B can cover 1600m2/17222ft2 (12B) and up to 2300m2/24756 (7B) to control river bank erosion.

With Tiltex B, 1 roll is installed in less than 20 minutes making travel, cartage and installation times reduce by more than half and offering long term erosion control solution.

Tiltex’s Latest Project Videos

Tiltex 7B & 12B installed by our expert team for erosion control of a main drainage channel over a large catchment area for an infrastructure development project.

Tiltex 10 was used to cover 30,000m2/322917ft2 of effluent pond batter slopes to protect the HDPE liner from exposure to UV radiation, heat sensitivity, bush fires, feral animals, livestock & to minimise vandalism.

Tiltex 80MPa/11,000psi+ Compressive Strength Concrete In A Roll was used in a 28 acre/0.4sq mile residential development as a stormwater collection basin.